Facilities

With an already substantial indoor and outdoor operations facility in Whitewater, Ontario, GlassHouse Botanics is focused on increasing our EU GMP capacity to supply the vast European market. Detailed expansion plans are being developed to maximize our 14 acres of land, with the ability to significantly increase our footprint.

Overview

Our commitment to superior quality motivates the team at GlassHouse Botanics. We provide our cannabis plants with the optimal environment to flourish, and produce world-class products in extraordinary quantities as a result.

Future-focused technology

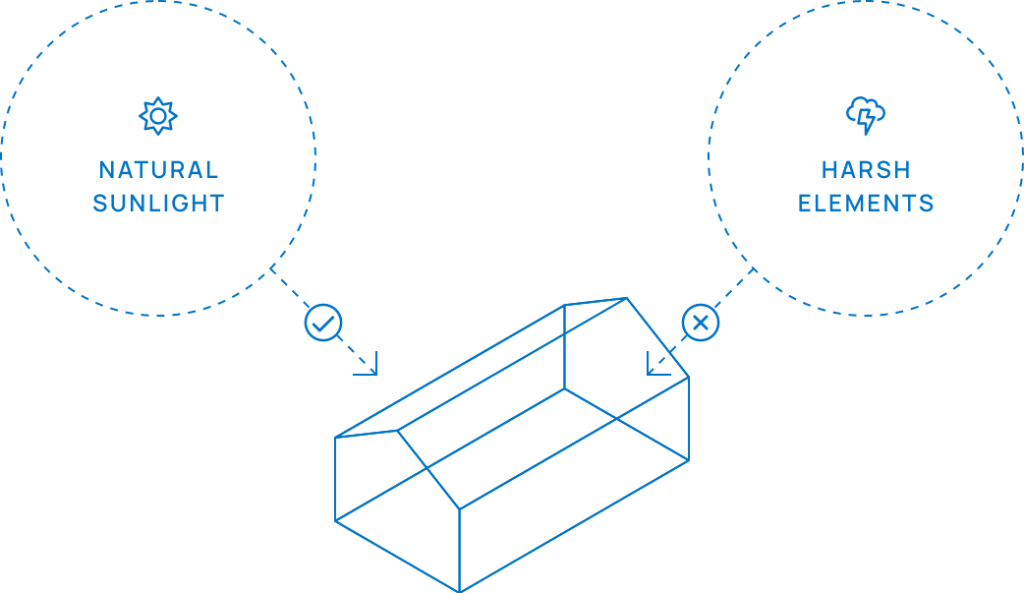

GlassHouse Botanics has built an indoor growing facility that is truly cutting edge. Our top-of-the-line greenhouses provide our plants with all the advantages that natural sunlight and protection from harsh elements can provide. Our sophisticated technology takes care of the rest, bringing our greenhouses – and our products – to the next level of productivity.

Dynamic environmental control

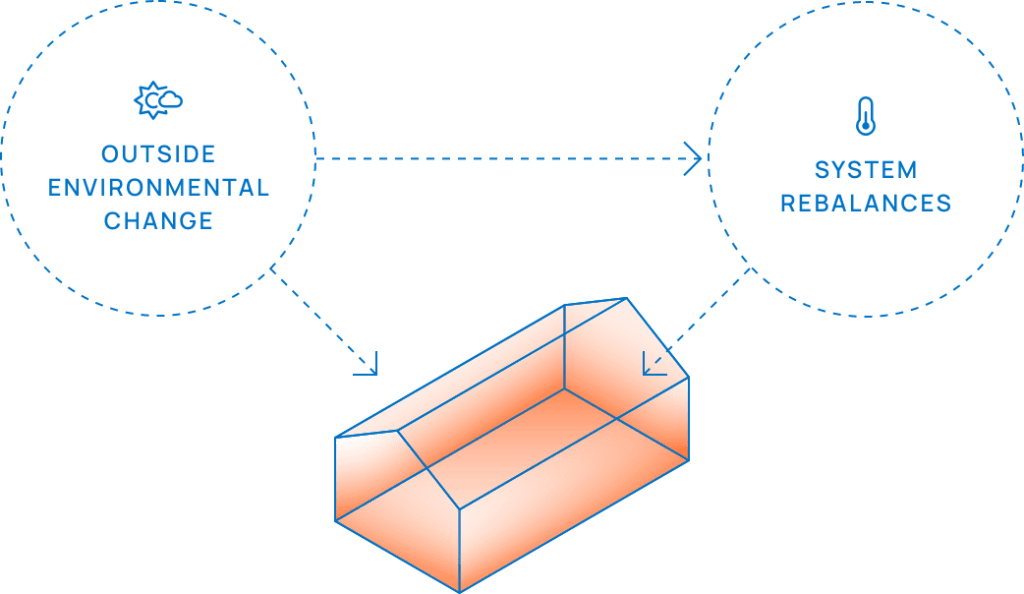

The precisely calibrated and optimally balanced environmental conditions that we use to grow our superior products are dynamically controlled by GlassHouse Botanics’ state-of-the-art greenhouse system. Any change outside that can affect the greenhouse environment – temperature, humidity, barometric pressure, shifts in the wind, cloud build up, rain or excessive sun – triggers a rebalancing of the system. This ensures our products reach their full growth potential with every crop.

Outdoor growing – Fresh frozen

To fully maximize the returns on our 14 acres of farmland, GlassHouse Botanics has obtained a licence for an outdoor growing operation. After installing thousands of irrigation lines, we are now growing our cannabis clones in 30-gallon pots outside in summer. Our annual harvest is looking stronger than ever! In 2021, we licensed a 7,000 cubic foot freezer/secure storage in the field for our flower so it can be used to make high-quality extracts. Our freezer has the capacity for more than 10,000 kg of fresh frozen cannabis flower.

EU GMP Certified Processing

EU GMP-certified facilities must demonstrate a capability to process cannabis according to strict regulations. From airflow continually being purified through HEPA filters, to our walls, floors, ceilings and equipment constantly being sanitized, our cannabis could not be produced in a safer environment. At GlassHouse Botanics, our processing rooms are pharmaceutical grade.

Each room and hallway in our facility is constructed and maintained in accordance with precise specifications. Our rigorous standard operating procedures meet the stringent requirements of EU GMP certification.

Expansion plans

GlassHouse Botanics is currently cloning and harvesting between 1200 and 1600 plants bi-weekly; resulting in approximately 150 to 200kg per month of high quality flower being produced for our clients.

The pending issuance of our EU GMP certification has significantly increased demand for our cannabis overseas. We therefore have drafted expansion plans to ensure we are able to address the increased demand we are seeing. Our expanded operation will include several drying, trimming and packaging rooms – all EU GMP certified, which will ensure products consistently meet specifications.

Most importantly, our new facility will be carbon neutral. It will utilize solar power, minimize power usage, recycle water and remain on the cutting edge of technology – with the goal of maximizing returns without harming the environment.

We’re thrilled to continue to develop as a company and discover new products for our customers around the world as we strive to be a leader in the medical cannabis space. The future is limitless!